Technology that makes a difference

Superb Product Quality

The Krieger C-TF Homogeniser with "Balanced Shear Force"

This self cleaning homogeniser makes

it difficult to lose batches due to

over-homogenising and safeguards

valuable shear sensitive ingredients

and API's.

Scientific Research published in the

Journal of Pharmaceutical Sciences

confirms the Krieger

"Balanced Shear force"

FDA - and ATEX certified for Zone 0

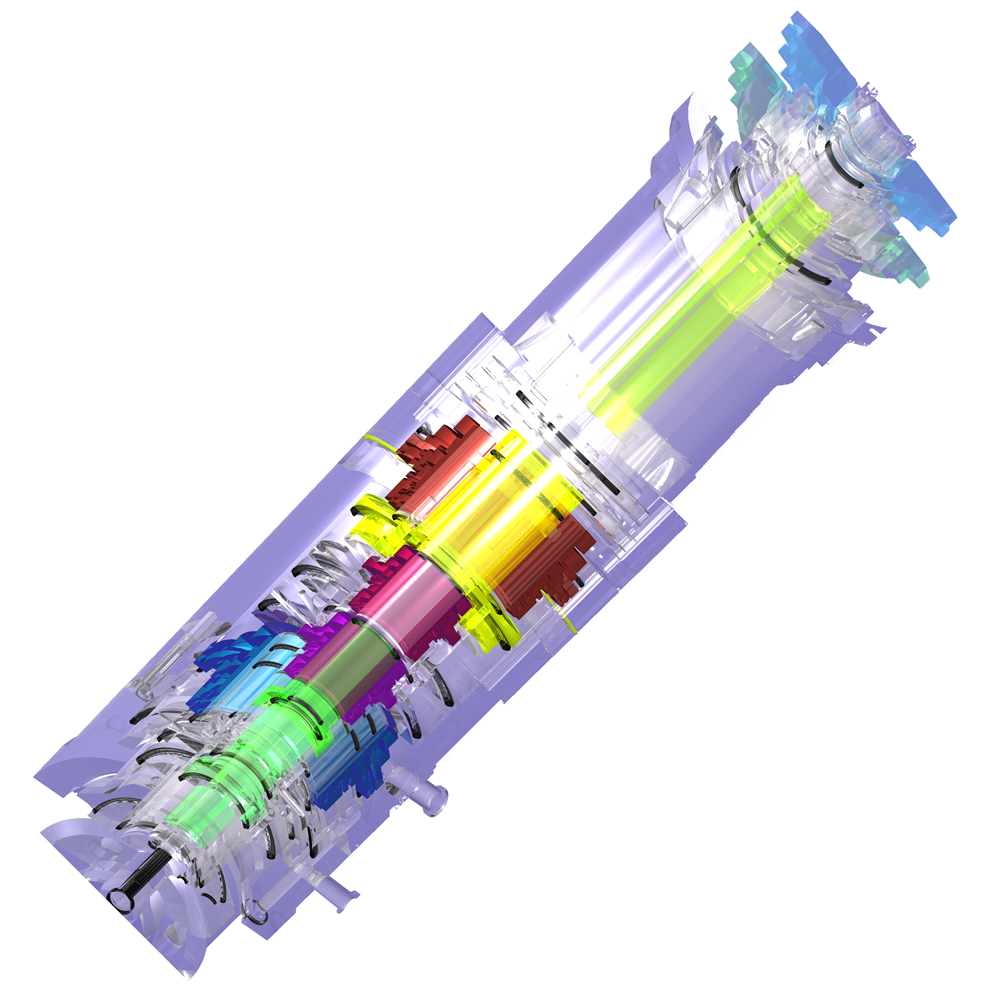

Fast Cleaning and Sterilisation

Krieger CIP/SIP gearbox with hight performance CIP/SIP system

The Famous Krieger counter rotating agitatir mixing system is operated by a high tech gear box that integrates a performant CIP/SIP system that brings the cleaning medium, the sterile steam for sanitisation or sterilisation and the dry air direct underneath the nozzles, mannhole and various selected places in the vessel were it’s most needed.

The Krieger system is faster and consumes less resources to achieve perfect processing results

FDA - and ATEX certified for Zone 0

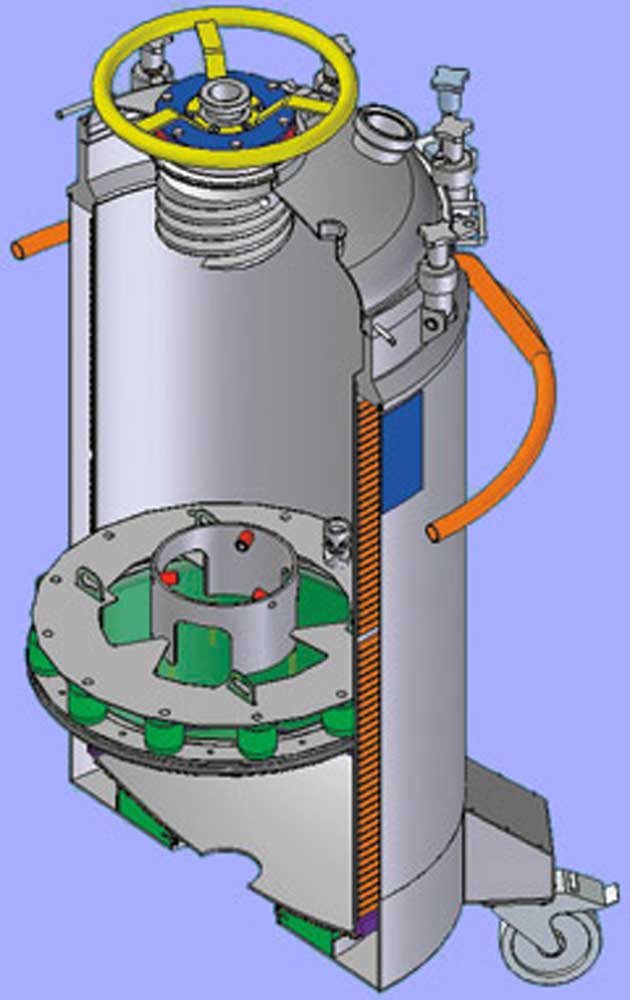

100% Containment

Krieger Seal Containment Chamber

This Krieger Technological breakthrough eliminates cooling liquids and seal and scraper debris in Sterile and Contained Systems and

makes our contained mixing technology the forerunner for products like:

Viscoelastics, Viscous Injectables, Hyaluronan based Gels, Injectable gels with controlled drug release, Cross linked gels and complex Contained/Sterile products.

FDA certified and high pressure execution

NEW processing technology for manufacturing high molecular weight cross linked hyaluronic acid based cosmeceuticals. (classified as injectable fillers)

The Krieger HA manufacturing plant integrates cross linking vessel, gel sizing, purifying and final particle reduction of the finished gel in one seamless to use processing unit.

More about Cosmeceuticals

Creams and

Ointments

The K- Mix building Block design allows to select and configure the mixing & homogenising equipment for low to high viscous semi solids, ranging from simple vacuum processing to processing under the most stringent sterile and, hazardous and toxic conditions.

Various building blocks for CIP, SIP, mixing tools, high speed dissolvers and homogenisers can be chosen from.

More about Creams & Ointments

Krieger’s series of biologics micro mixer tanks are specially designed for developing and validating on a small scale, fast and efficient new Biologics that can be scaled directly to your production tanks.

Sized from 100 ml onwards these small tanks mimic exactly your Fluid mixing Pattern of your manufacturing tanks.

More about Biologics Development

Quality by Design – QbD

Krieger has a proven track record for Quality by Design (QbD) Projects.

Our international engineering team develops and designs new types of processing equipment based on the knowledge of our customers, research findings and Kriegers processing excellence know how.

More about Quality by Design